Fish Feed Extruder: Advanced Technology for High-Quality Aquaculture Feed

As global aquaculture continues to expand, the demand for nutritionally balanced and highly efficient fish…

As global aquaculture continues to expand, the demand for nutritionally balanced and highly efficient fish feed is increasing rapidly. A fish feed extruder is a key piece of equipment used to produce floating or sinking aquatic feed with excellent water stability and digestibility. By applying precise control over temperature, pressure, and moisture, fish feed extruders…

Introduction Sawdust is one of the most abundant by-products of the global wood-processing industry. For decades, it was often treated as low-value waste, requiring disposal through landfilling or open burning. With the growing emphasis on renewable energy, waste reduction, and circular resource utilization, sawdust has gained new importance as a valuable biomass material. As a…

In the field of organic fertilizer production, the choice of raw materials is critical in determining the quality and effectiveness of the final product. To produce a high-quality fertilizer that meets the needs of modern agriculture, sourcing the right materials and implementing stringent quality control measures are crucial steps in the production process. This article…

1. Introduction In the production of organic fertilizers, high – moisture raw materials are commonly encountered. These raw materials, such as fresh manure, certain types of wet compost, and some industrial organic waste, pose significant challenges to the operation of organic fertilizer pelletizers. High – moisture content can lead to problems such as poor granulation,…

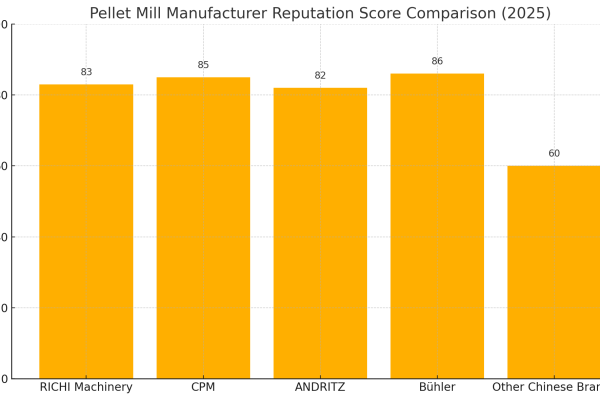

Choosing a reliable pellet mill manufacturer can make or break your business. Whether you’re producing animal feed, biomass fuel, or organic fertilizer pellets, your equipment must perform consistently, deliver high output, and come with real support behind it. So, which pellet mill manufacturers have the best reputation in the global market today? Let’s break it…

A commercial fish feed production line is a comprehensive system designed to manufacture feed pellets for aquatic animals on an industrial scale. It typically includes several stages, from raw material preparation to the final packaging of the feed pellets. The technology behind fish feed production lines is sophisticated and designed to ensure high-quality feed production….

Floating fish feed production involves several steps, each crucial to the quality and nutritional value of the final product. The process begins with the selection of raw materials, which typically include grains, soybean meal, fish meal, and other protein sources. These ingredients are then ground into a fine powder to ensure better digestion by the…

The aquaculture industry has experienced significant growth in recent years, driven by the increasing global demand for seafood. To meet this demand, fish farmers require high-quality, nutrient-dense feed that promotes the health and growth of their aquatic livestock. Feed factory machines play a crucial role in the production of aquatic feed, ensuring consistency, efficiency, and…

The quality of animal feed is paramount for the health and productivity of livestock and poultry. As the demand for high-quality feed continues to rise, manufacturers must implement effective strategies to ensure that their animal feed manufacturing machines produce consistent, safe, and nutritious products. This article explores the key practices and measures that can be…

The efficient and reliable operation of an animal feed milling machine is crucial for maintaining consistent feed quality and production output. Regular maintenance is essential to prevent breakdowns, minimize downtime, and extend the lifespan of the machine. While there are many aspects to consider in an effective maintenance program, this article will focus on the…