Mussels are a healthy choice for the environment and consumers. Removed from the stress of near-shore waters, they grow thinner shells and larger meats. They feed on naturally occurring microscopic plants—free of additives—and are a lean, healthy protein source.

A commercial fisherman is using this technology to launch the first commercial offshore mussel farm in the U.S. At its current size of 12 lines, this farm can produce up to 150,000 pounds of mussels annually. Look for “Isle of Shoal Supremes” in seafood markets this winter!

Design

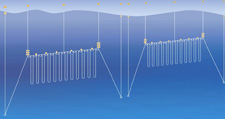

Each longline spans 600 feet and is anchored at each end to the sea floor by two-ton granite blocks. Two clusters of submersible floats raise the line to form the corners of a horizontal backbone from which loops of mussel grow-out ropes are suspended. Additional floats along the backbone help maintain the line at the desired depth as the mussels gain weight during growout. On the surface, all that is visible are three buoys, one tethered to each granite anchor to mark the location of the longline, and one attached to the center point of the backbone for raising the line to the surface.

Seed

Mussels are prolific broadcast spawners and the free swimming larva are abundant in the plankton at certain times of the year. Juvenile mussels or “seed” can be collected from the wild with ropes or other substrates that attract settlement of mussel larvae. Seed for the project and for commercial operations has been collected on ropes suspended from the offshore longlines and from the netting of the fish cages. Research has demonstrated that with the proper timing, location, and collection materials, wild seed collection is a reliable source of juvenile mussels.

Socking

After several months on the seed collectors the mussels have grown to approximately 1 inch (25 mm), and are ready for the next step in the culture process. The tiny mussels are stripped from the collectors, de-clumped and sorted by size. They are then fed into a custom-designed seeding machine, based on New Zealand technology, that funnels the mussels into a distribution chamber.

A growout rope is pulled through this chamber where it picks up the mussel seed and then passes through a tube where the rope and seed are sheathed in biodegradable mesh cotton sock. The cotton socking material keeps the seed in place until the mussels have a chance to attach. The strong rope core allows farmers to extend the length of the growout lines and take advantage of vertical depth in the open ocean.

Growout

Grow out takes nine to eleven months, during which the farmer must periodically inspect the seeded lines and maintain the depth most appropriate for growth. Mussel samples are taken on a monthly basis to inspect meat quality, track growth, and estimate the total biomass. Additional submersible floats are added to the backbone to compensate for the increased weight of the growing mussels.

Harvest

When the mussels grow to 55 mm, they are ready for market. They are removed from the growing ropes using a custom-designed stripping machine and then washed, declumped, and de-bearded for marketing.

Offshore mussels are raised in a less turbulent environment than those farmed near shore, and therefore have thinner shells and higher meat content. While this a desirable product for the consumer, the mussels are more fragile and require more gentle handling. We have been working with commercial operators to adapt equipment to process market-ready mussels on board and avoid addition shoreside processing.

Submerged offshore culture produces a clean product with no grit, so there’s no need to purge the shellfish with water as is customary with inshore farmed mussels.